General Product Information

ROCKWOOL stone wool products are made of basalt, a volcanic stone.

ROCKWOOL stone wool products are non-combustible with a melting point of approximately 1000°C. They are particularly suitable for thermal insulation, fire protection and sound reduction/absorption.

ROCKWOOL stone wool is inorganic and contains no nutritious substance. Therefore it will not be attacked by microorganisms. Stone wool will not rot and does not attract vermin. No CFCs, HFCs, HCFCs or asbestos are used in the manufacture of ROCKWOOL stone wool products.

Common Applications

RockTech S is particularly suited to meet the specification requirements of thermal insulation, fire protection and sound attenuation of both flat and slightly curved surfaces of tanks, vessels, boilers and ducts. The fibre structure of RockTech S provides the product with great dimensional stability and pressure resistance.

RockTech S is normally used to insulate and achieve the desired surface temperature and minimize the heat loss from equipment, thus providing energy saving to the overall process. Specially formulated RockTech S850 product is designated to be used for maximum service temperature of up to 850°C. The optimum thickness to be used can be calculated with the use of sophisticated thermal insulation software available in ROCKWOOL with the selected RockTech S series product.

Basic installation guideline

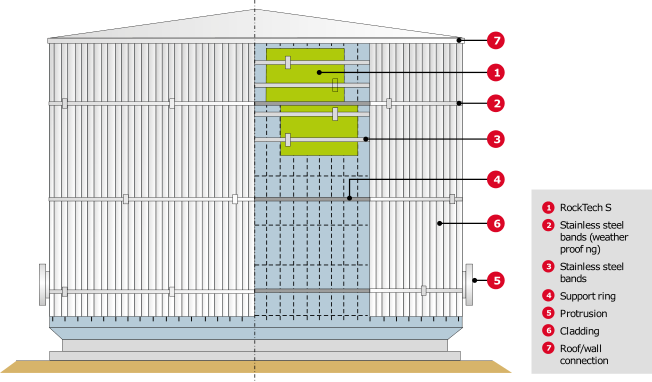

RockTech S can be easily cut to required shape, length and width with a use of a handsaw or a sharp knife. RockTech S is securely fastened to the equipment to be insulated with the use of insulation pins which is either mechanically fastened

Application

or spot welded onto the surface of the equipment. The edges of each slab should be butt jointed closely together. All steel components or equipment to be insulated which is exposed to a corrosive environment should be cleaned, de-greased and coated with a protective finish before insulation is installed onto it.

The insulation should be finished with metal cladding i.e. aluminum or other approved cladding material. Both lengthwise and circular joints of the cladding are fastened with sheet metal screws or rivets. All the connections within the cladding should be made watertight using suitable sealant. In the event aluminum foil faced finishing is preferred, finished lengthwise and crosswise joints with a self-adhesive aluminum tape (? 75mm width). When the insulating equipment is colder than the ambient temperature, and there is a risk of condensation, the insulation should be provided with a vapour barrier.

Packaging and storage

RockTech S is shrink-wrapped in polyethylene sheets for ease of handling, transportation, storage and identification. Products should be stored indoors or under a waterproof covering.

Ensure the insulation is not in direct contact with the floor; otherwise it may become wet as a result of ground moisture.

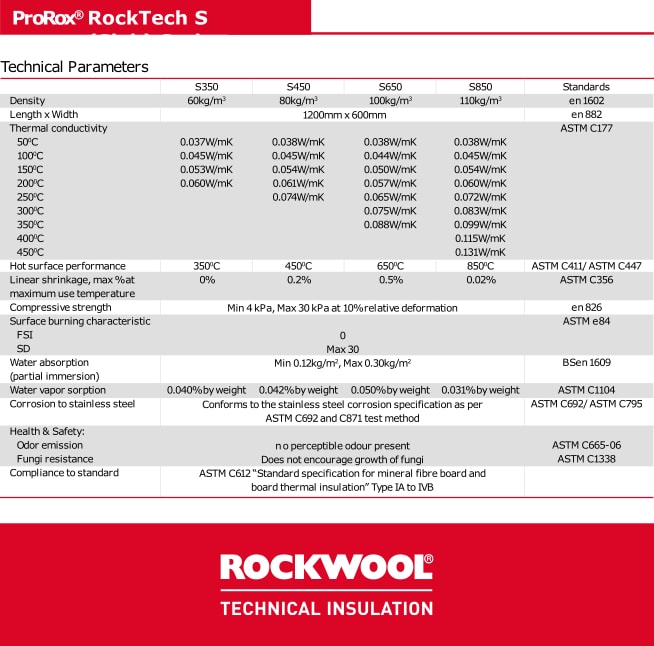

Product Properties